Build-to-print Manufacturing

From Concept to Completion: Your Design, Our Expertise

Our team is committed to simplifying the manufacturing process while ensuring efficiency and quality every step of the way.

We take the stress out of manufacturing your machine while still providing the comfort and knowledge that it’s being designed to meet your quality and technical standards.

If requested, we can provide additional expertise by utilizing our experienced engineers to increase manufacturability and increase cost savings. This could be small scale such as making drawings for us to manufacture internally, or it could be large scale offering the customer a full redesign of their equipment using best practice engineering and manufacturing.

Manufacturing Services

Looking for CNC machining, cutting, fabrication, powder coating or pre-engineered services?

Arnold Machine is a full-service, one-stop-shop. We have modern equipment, highly skilled staff and the capacity to take on any sized project.

We utilize HAAS automation tool builder, MAZAK vertical machining centers and CNC lathes. We can machine parts up to 120” long, 60” wide, and 30” tall.

Skilled fabricators at Arnold Machine specialize in MIG, TIG, steel, stainless steel and aluminum welding applicable to many industries and product mixes. Our in-house certified welding instructor ensures our fabricators are trained and certified to perform any welding operation to meet customer requirements. Additionally, we employ skilled mechanical and electrical assembly technicians capable of a wide variety of contract assembly jobs.

CNC Machining

CNC machining is a manufacturing process in which pre-programmed computer software dictates the movement of factory tools and machinery. The process can be used to control a range of complex machinery, from grinders and lathes to mills and CNC routers.

We have full 5-axis capabilities and strive for quality control using FaroArm.

Machining Capabilities:

- MAZAK INTEGREX I-300

- MAZAK INTEGREX I-200

- MAZAK VMC – VCN-530C

- HAAS VF3 VMC

- HAAS VF6 VMC

- HAAS VF2 VMC

- HAAS ST10 lathe

- HAAS ST20 lathe

- HAAS GR510 gantry

- HAAS TM-2

- Gibbs and Esprit CAM Software

Fabrication

Our fab shop is comprised of some of the most knowledgeable welders in manufacturing. They can provide superior TIG, MIG and Pulse MIG welding from small detailed widgets to complex, large frames.

Fabrication Capabilities:

- Miller MIG welders

- Miller TIG welder

- Lincoln MIG welders

Sheet Metal Cutting

We have a brand new TRUMPF TruLaser 1030 6KW Fiber cutter for cutting a wide range of sheet metals and thickness. This system is fast and efficient.

For creating forms and configurations from sheet metal laser cuts, we have a CNC Press Brake available.

Sheet metal equipment:

- TRUMPF 6KW Fiber Laser

- ACCURPRESS 150-ton press brake

- RADAN nesting software

- MILD STEEL, ALUMINUM, AND STAINLESS STEEL FABRICATION

Powder Coating

To finish any process, Arnold Machine has in-house powder coating services with no minimum part size or quantity requirements. We also have a large spray booth and cure oven allowing us to powder coat items up to 15 feet long, 12 feet wide and 12 feet tall.

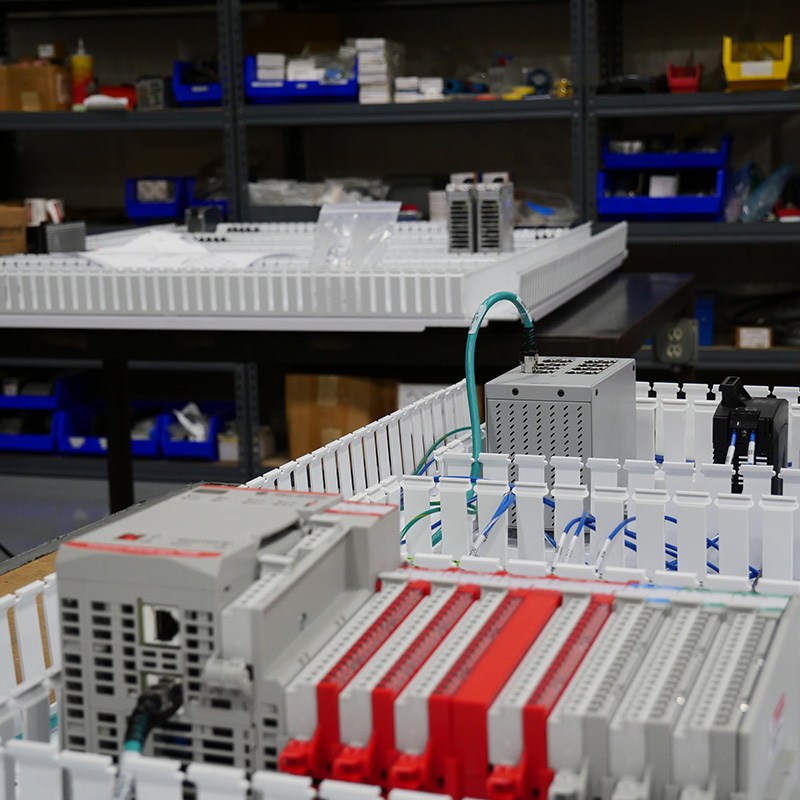

Mechanical and Electrical Assembly

- Building electrical panels

- Complete panel installation and field wiring

- Controls system upgrades

- Contract mechanical assembly operations

- Controls system redesign and changeover

Contract Manufacturing

Our contract manufacturing experts at Arnold Machine partner with customers to solve problems and create opportunities that increase production output and quality and generate better long-term ROI.

Once purchased, Arnold Machine will dedicate a project manager to your project to ensure that everything is manufactured and built smoothly. With a build to print project, we can release drawings to the shop immediately after PO rather than waiting on engineering to develop the design. Our expertise allows us to make decisions that could improve the project’s manufacturability, pricing, and longevity.

If you think something’s holding your manufacturing process back, we should talk. Contact us now.

Arnold Machine’s capabilities include designing and building:

- Any equipment or machinery that a customer uses to manufacture their own products.

- Manually operated machinery.

- Automation machinery

- Simple weldments such as benches, tables, drying racks, light fixtures

- Testing fixtures for any R&D

- Anything that already has a design whether it is a 3D model or 2D drawing

If you’re new to automation, see our ROI calculator and resources to help you in the research process.