Anti-Vibration

Anti-vibration systems are unsung heroes.

Found in a number of industries with a wide-range of applications, anti-vibration systems are a critical component to many automated processes. Why? Because if something vibrates, it can wreak havoc.

For manufacturers to stay profitable, their equipment must be smarter and more resilient.

That means the right equipment provider must be equal parts cartographer and guide, a combination that the engineers at Arnold Machine have mastered since 1994.

We have leveraged our understanding of rubber-to-metal bonding to design, build and install anti-vibration component assembly equipment for a wide variety of parts.

In the automotive industry for example, anti-vibration mounts are critical to safe, comfortable automobile travel.

They reduce risk of damage to mechanical and structural systems, quiet the noise resulting from parts in constant motion and eliminate passenger discomfort associated with intense vibration.

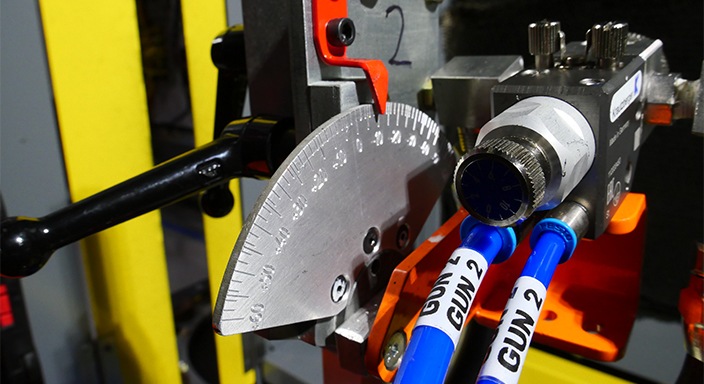

Our decades of experience has proven that first and foremost, anti-vibration mounts are worthless if they do not properly adhere to the metal components connecting them to a chassis. That’s why the rubber-to-metal bonding process requires precision and care. And while human workers are certainly capable of precise work, they’re not perfect.

Profitable manufacturing depends on turning out high-quality parts very quickly. Increasingly, human labor is more of a liability than an asset in these scenarios. Incorporating a custom-automated machine guarantees quality at a high volume, reduced scrap rates and rework, and controlled material costs.

If you think something’s holding your anti-vibration assembly process back, we should talk. Contact us now.

As in any of our custom automated systems, we collaborate with you to find the best solution for your unique challenges.

Whether you’re new to anti-vibration automation or have integrated other automated systems before, we work with you from design to installation, and even once it’s up and running to provide the services you need.

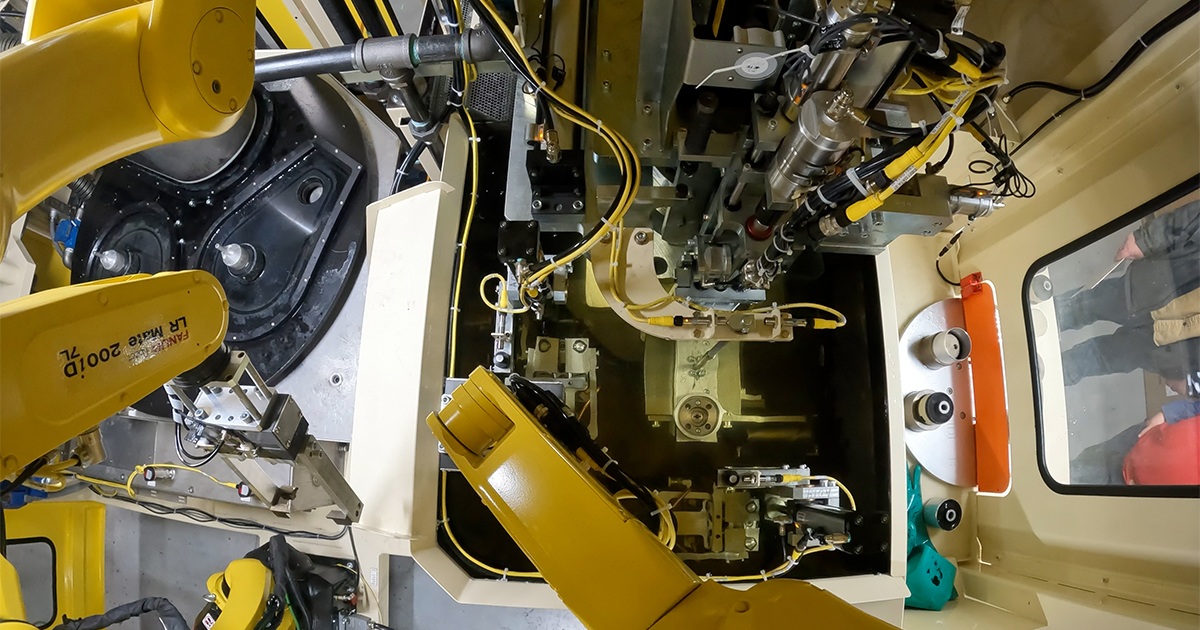

We are proud integration partners of FANUC and Rockwell Automation. Through these partnerships, our engineering and technical support staff are kept up to date on the latest technological advancements in automation. This allows us to offer our customers training programs through FANUC or Rockwell Automation, ensuring they have the resources they need to be successful.

For lower-volume processes requiring only one or two operators, we offer 100% custom-engineered systems precisely tailored to your facility and operational requirements.

In high-volume applications traditionally requiring more than two or three operators, the AMI Flexible Automation platform is the ideal solution to reduce error, boost consistency and meet throughput requirements at mass scale.

Whatever your vibration challenges are, we will work with you to develop an automated system that is equipped to handle any challenges that arise, quickly and efficiently.

We have amassed a large portfolio of custom anti-vibration part assembly solutions, and we are certain we can provide a solution for you.

We have designed, built and installed anti-vibration component assembly equipment for a wide variety of parts including:

- Solid rubber engine & transmission mounts

- Hydraulic engine & transmission mounts

- Exhaust mounts

- Sub-frame mounts

- Differential mounts

- Solid rubber suspension bushings

- Fluid-filled suspension bushings

- Strut mounts

- Cab mounts

- Process automation expertise

Methods for automating mount assembly vary based on their application. Some are solid molded rubber, so manufacturing stops after the rubber is bonded to metal assemblies. Others are made of hollow rubber filled with fluid—usually glycol.

In this manufacturers guide, we discuss two different scenarios where our team developed automated manufacturing systems for glycol-filled mounts. The case studies explain how we helped major automotive suppliers meet their unique challenges head-on.

Anti-vibration systems must be faster and more reliable than ever before.

If you’re new to automation, see our ROI calculator and resources—or case studies and guides below—to help you in the research process.