CLEANING COMPLEX & DELICATE PARTS WITH ROTARY BASKET WASHERS

Manually washing delicate and complex parts often leads to quality control issues. As such, it’s incredibly challenging to meet strict cleanliness specifications. Engineering managers need a reliable way to wash intricate components thoroughly and consistently.

Arnold Machine rotary basket parts washers provide an ideal solution to address and solve these challenges. They effectively clean high volumes of parts to exact specifications while reducing labor requirements.

Read on to learn how this advanced parts-washing technology can improve your manufacturing processes.

HOW DO ROTARY BASKET WASHERS WORK?

Rotary basket washers use an internal rotating basket to cycle parts through spray jets or immersion baths filled with cleaning fluids. These industrial parts washers come in spray-only, partial, or full immersion configurations. Standard or custom baskets and fixtures accommodate various part sizes and geometries.

There are many available options such as multi-stage washing, specialized filtration, heated chemical rinses, and more. Users can tailor cycle times, cleaning methods, and other important parameters to ensure optimal cleaning results.

Standard features include:

- Adjustable Rotation Speeds: Rotary basket washers allow users to customize the rotation speed of the basket based on the part needs. Faster speeds provide more vigorous agitation for harsh contaminants, while slower speeds gently clean delicate items. This configurability ensures optimal results for diverse components.

- Dedicated Rinse Cycles: Purified rinse cycles remove cleaning agents and prevent residue buildup. Applications with strict cleanliness standards often require a rinse stage to avoid water spots on finished surfaces.

- Load/Unload Automation: Automatic loading, unloading, and robotics streamline the process and reduce labor requirements. Customized basket fixtures also secure delicate parts in place, avoiding collisions during basket rotation.

- Precision Filtration: Specialized filtration configurations, like fine mesh screen filters, effectively filter tiny particulates from the cleaning and rinsing fluids. This level of precision meets the needs of applications requiring stringent cleanliness and particulate removal.

- Custom Wash Programming: Programmable controls allow users to create customized wash cycles tailored to each part type. This includes adjusting cycle times, wash and rinse temperatures, and rotation speeds to optimize cleaning.

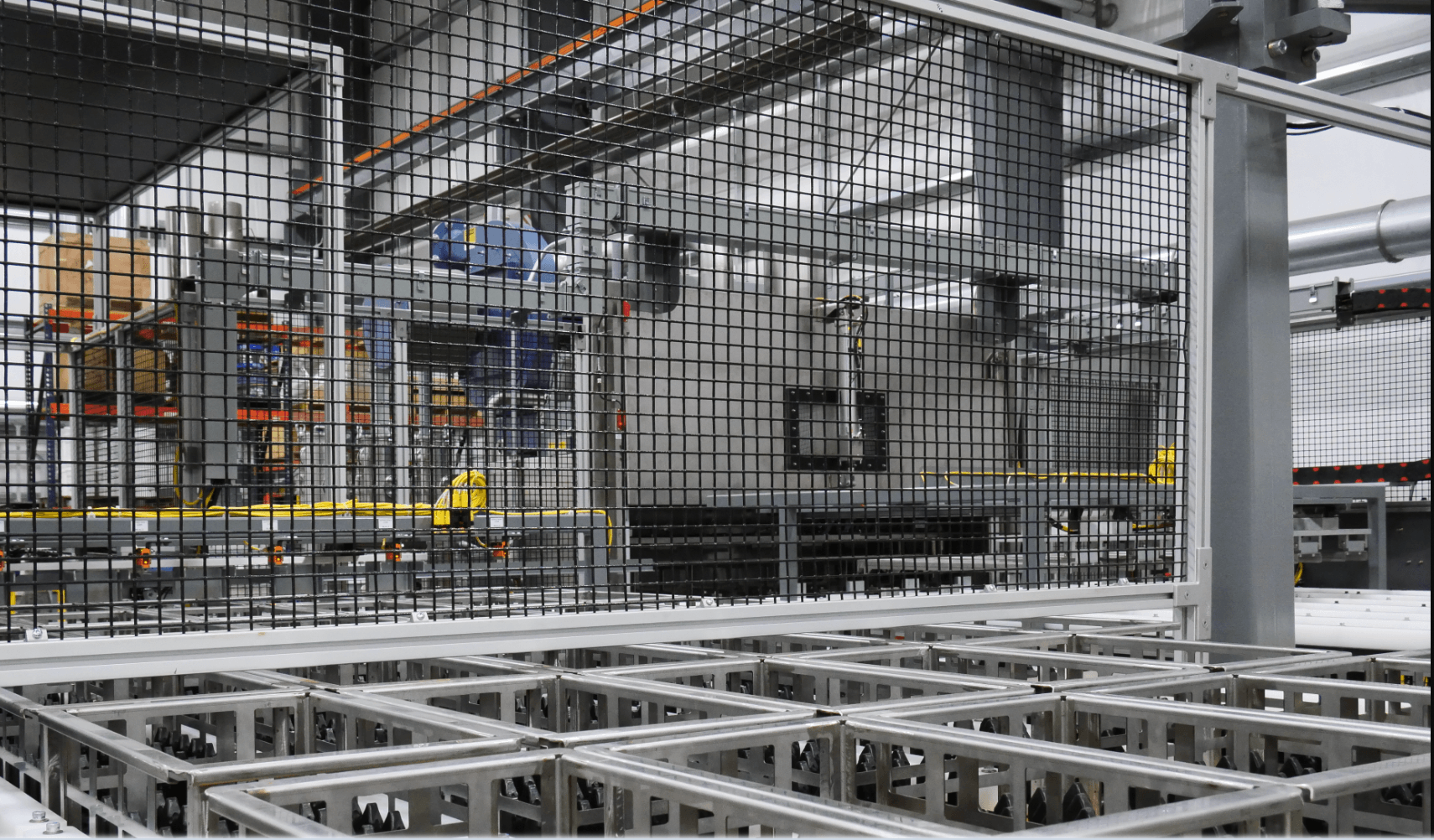

Watch this video to see an Arnold Machine rotary basket washer in action:

ROTARY BASKET PARTS WASHERS BENEFITS

Rotary basket parts washers offer unmatched cleaning efficiency for intricate and delicate parts. Their advanced technology surpasses manual methods, ensuring consistent and thorough cleaning.

Benefits include:

- Enhanced Safety: Automated processes reduce the risk of injury associated with manual cleaning. Workers won’t get exposed to hazardous cleaning chemicals.

- Improved Quality Control: Consistent cleaning results lead to better quality control in manufacturing processes.

- Scalability: Can clean small batches or high volumes for large-scale production. This flexibility makes them scalable for all throughput needs.

- Cost-Effectiveness Over Time: Reduced labor costs and improved efficiency can lead to long-term cost savings.

- Extended Part Lifespan: Gentle cleaning of delicate parts can prolong the life of parts by avoiding damage during cleaning.

- Reduced labor costs: One operator with a rotary basket washer can achieve higher output than several workers manually washing parts.

INDUSTRIES AND APPLICATIONS

Industries like automotive, aerospace, agriculture, and construction utilize rotary basket washers for small, complex parts. Example components include ammunition magazines, fuel system parts, valves, and gears.

The high degree of customization of rotary parts washers meets diverse industry needs. Typical configurations for delicate parts include:

- Low-Pressure Spray Settings: Utilizing a lower pressure for spray nozzles helps gently wash delicate parts without causing damage.

- Ultrasonic Cleaning: This method uses high-frequency sound waves to clean intricate parts thoroughly. It's particularly effective for removing contaminants from hard-to-reach areas without physical abrasion.

- Customized Basket Design: Baskets can be specially designed or lined with protective materials to hold small, delicate parts securely. This also prevents them from colliding or getting damaged during the washing process.

- Partial or Full Immersion With Gentle Agitation: Immersing parts in cleaning solutions and employing gentle agitation helps thoroughly clean without harsh mechanical action.

- Variable Speed Controls: Adjusting the rotation speed of the basket allows you to fine-tune cleaning customization.

- Temperature Control: Some delicate parts may require specific temperature settings during the cleaning process to prevent damage.

- Dedicated Rinse Cycles: Rinse cycles with deionized or distilled water can help prevent residue from forming.

ROTARY BASKET WASHERS VS. OTHER CLEANING METHODS

Compared to manual washing, rotary basket washers provide superior effectiveness and efficiency in their performance. They automate the cleaning process, ensuring consistent cleanliness that manual methods can't match. This automation delivers uniform results and reduces labor requirements.

Compared to other industrial cleaners like belt washers, rotary basket washers shine in their ability to handle delicate parts. Belt washers work well for cleaning large volumes but often lack the necessary features for fragile items. Alternatively, you can tailor a rotary basket washer to meet your requirements.

The automated workflow in rotary basket washers adds to their efficiency. This system streamlines cleaning complex parts, thereby maintaining high standards of cleanliness for each part. Their gentle yet effective cleaning approach makes them ideal for intricate engineering applications where precision is key.

SMALL, COMPLEX, AND DELICATE PART CLEANING SOLUTIONS

Arnold Machine engineers and manufactures high-performance rotary basket parts washers. Decades of experience make us the industry experts in cleaning intricate components to high cleanliness specifications. Click below to explore our rotary basket washers page.