PARTS CLEANING EQUIPMENT DESIGNED FOR THE END USER

Industrial parts washers reduce labor requirements, improve cleanliness, and increase worker safety. However, frequent equipment breakdowns and short lifespans negate these benefits and create significant operational challenges. At Arnold Machine, we understand the frustrations caused by subpar parts washing equipment. That is why we purpose-engineer our industrial automatic parts washers to stand up to the test of time and deliver exceptional performance. Read on to learn how our customer-focused design and approach make us the go-to choice for companies seeking a superior parts cleaning solution.

COLLABORATING TO UNDERSTAND YOUR REQUIREMENTS

Understanding your parts-washing goals is essential for us to engineer the proper solution. We start by gathering essential information such as parts models, target production rates, cleanliness specifications, facility layout, etc.

When collaborating with our customers, our engineers often ask critical questions like “How clean is clean?” and “How dry is dry?” This is important as acceptable cleanliness and dryness specifications vary widely between customers, industries, and applications.

Other examples of questions that our engineering team asks include:

- What is the available footprint?

- Natural gas or electric heat?

- Are there mechanical or electrical specifications that need adherence?

- Stainless steel or carbon steel construction?

- What part models are you washing?

- How many parts per hour need cleaning?

- What load/unload automation is needed?

Our customers also have the unique flexibility to incorporate specialized features. With this meticulous collaboration, we develop a roadmap to custom-engineer optimized parts washers aligned with your goals.

CUSTOM ENGINEERING BASED ON YOUR NEEDS

We use your requirements to guide us when engineering components. For example, we can right-size the wash chamber to fit the expected throughput while minimizing the footprint. Or use chemical-resistant materials capable of withstanding specific cleaning agents.

Our intelligent designs can also include tank top accessibility to internal components like chip baskets, level control floats, water makeup, pumps, etc. Prioritizing usability factors like these is crucial for creating equipment that simplifies maintenance and operation for the end user.

In designing for usability, we consider everything regarding ease of operation and maintenance. For instance, we incorporate large doors to enable access to the upper housing and tank for cleaning, loading, and maintenance.

Enhancing ease of maintenance also includes offering innovative features like filter bag pressure sensors that alert operators to needed changes. Proactively anticipating these maintenance issues keeps equipment uptime maximized.

LEVERAGING ADVANCED DESIGNS

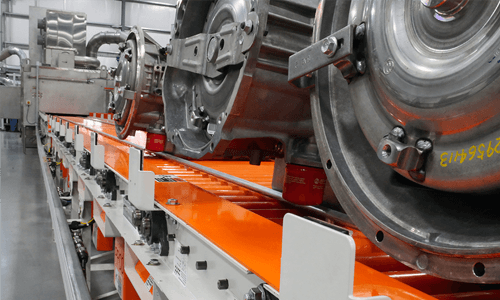

Our parts washers incorporate many innovations that deliver real-world benefits. Gull-wing doors provide generous workspace when servicing internal components like nozzles and headers. Advanced sensor systems continuously monitor critical parts to minimize unplanned downtime.

Efficient pumping systems recirculate solutions at rates tailored to your expected throughput. Insulated housings promote safety and conserve energy. We strive to identify and integrate impactful solutions that translate to real-world advantages.

VALIDATING PERFORMANCE THROUGH RIGOROUS TESTING

Our engineers and machine builders thoroughly test every industrial parts washer in-house before shipping them out. This careful approach ensures that the features, components, and systems work as intended in harsh manufacturing settings.

Our intensive validation process puts our machines through extensive operation simulations and stress tests. Parts washers run for hundreds of continuous hours under heavy use conditions. Temperature, pressure, and corrosion resistance measures confirm industrial-grade durability.

ENSURING RELIABILITY AND DURABILITY

We utilize innovative designs and parts that maximize performance and longevity. For example, we only use industrial-proven pumps, blowers, heaters, drives, etc. that are designed to take abuse and last for a long time.

We construct the external housing of our heavy-duty parts washers using high-grade steel. This steel construction is durable enough to withstand decades of use in harsh industrial conditions. Many of our industrial parts washers built over 35 years ago are still in daily operation today.

TRAINING AND TECHNICAL SUPPORT

We’re incredibly proud of our highly skilled service department. Our technicians have many years of experience servicing and supporting our equipment. The hands-on guidance they provide trains your staff to utilize the advanced capabilities of their customized parts washers.

Our technicians go beyond just installation and maintenance. They regularly meet with customers to analyze performance data and provide suggestions to maximize the effectiveness of their customized parts washers. This ongoing collaboration helps our customers optimize the efficiency of their parts cleaning operations.

RUGGED PARTS WASHERS ENGINEERED FOR YOUR SUCCESS

Our rigorous collaborating processes, custom engineering, and continual innovation deliver durable and high-performance industrial parts washers. Click below to discover the immense value our customized solutions can offer your organization.