SOLVING RUST & CORROSION WITH ROTARY BASKET PARTS WASHERS

Maintaining the integrity of industrial parts and equipment poses immense challenges. Rust and corrosion lead to major setbacks—from costly downtimes to the premature need for replacements. These problems ultimately impact not just productivity but profits as well.

Fortunately, there's a solution that addresses these concerns effectively. Imagine a system that cleans your components thoroughly and applies protective measures to guard against future deterioration. This advanced technology can transform your manufacturing parts washing process.

Rotary Basket Parts Washers from Arnold Machine combat rust and corrosion through multi-stage cleaning optimizations. Read on to learn how this innovative solution can protect your parts or equipment.

BENEFITS OF ROTARY BASKET PARTS WASHERS

Rotary Basket Parts Washers from Arnold Machine offer unparalleled efficiency and advanced technological integration. They can significantly extend the life of your equipment. The cost savings alone from avoiding frequent replacements can be substantial over time.

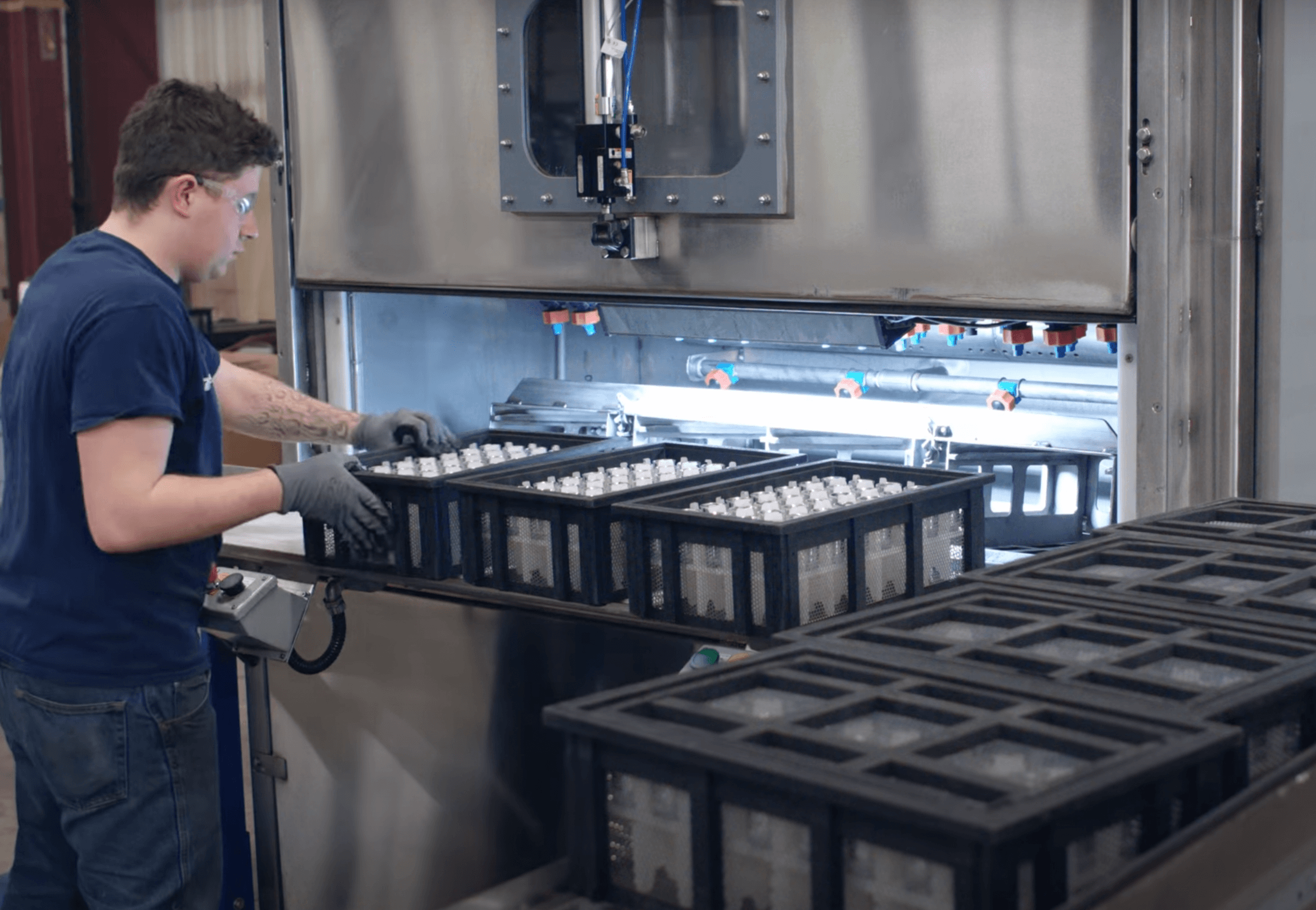

Check out this video for a demonstration of how our rotary basket parts washers work:

A series of groundbreaking features make our rotary basket parts washers stand out:

Advanced Automation: Our washers feature automated loading and unloading capabilities. This innovation reduces manual intervention, streamlines your workflow, and increases the overall efficiency of your cleaning process.

Robotic Integration: Integrating robotics into our machines allows for consistent, precise handling of components. This ensures each part meets exacting cleanliness standards regardless of size and complexity.

Customizable Solutions: We specialize in creating custom solutions tailored to fit any part size or shape. Whether you're dealing with small, delicate parts or larger items requiring specialized handling, we can adapt our rotary basket parts washers to meet your needs.

Multi-Stage Cleaning Process: Each washer comes standard with a multi-stage cleaning process including washing, rinsing, and blow-off stages. This ensures that every part exits the system thoroughly cleaned and ready for immediate use or further processing.

Full Automation Advantages: You’ll gain several advantages from transitioning from a manual to a fully automated system:

- Consistent part quality from minimized human error

- Reduced labor costs, especially for high-volume operations

Expertise in Customization: With over three decades of experience in the industry, we have honed our skills in crafting high-quality customized wash systems. We offer many options that extend beyond standard features:

- Specialized magnetic filtration systems for ferrous materials

- High-pressure spray options for stubborn contaminants

- Custom part fixturing for unique geometries

- Multistage washing capabilities for thorough cleanliness requirements

- Robotics integration for enhanced automation

Investing in an Arnold Machine Rotary Basket Parts Washer provides customizable cleaning precision to enhance your production capacity while maintaining stringent cleanliness standards.

Our commitment extends beyond the sale—we offer comprehensive support, including installation assistance and maintenance training to ensure you get the most out of your investment.

CAN ROTARY BASKET PARTS WASHERS FIX RUST OR CORROSION ALREADY ON THE PARTS?

You might be wondering if parts washers can fix rust or if parts washers can fix corrosion. Although the primary function of a rotary basket parts washer is prevention, it can potentially help restore parts that are already experiencing rust or corrosion. However, the effectiveness depends on the severity of the damage and the type of metal involved.

In some instances, additional treatments might be needed after washing to remove all traces of rust or corrosion fully. It's essential to consult with Arnold Machine experts to determine the best course of action for your specific situation.

PREVENTING RUST AND CORROSION

Solving rust issues with parts washers requires a specialized solution. We designed our rotary basket parts washers to automatically dispense the precise 3-7% rust-preventative solution balance necessary for maximum corrosion protection.

For example, if a rinse tank has a 200-gallon capacity, adding a 5% rust preventative ratio would consist of 10 gallons of preventative mixed with 190 gallons of water. This removes any guesswork around how much solution to use.

TAILORED SOLUTIONS FOR DIFFERENT MATERIALS

We can customize our rotary basket parts washers to clean different metal types effectively based on their specific needs. We highly recommend applying a rust-preventative solution in the final rinse stage when dealing with steel parts. Steel is susceptible to corrosion and greatly benefits from an added layer of protection.

On the other hand, aluminum and brass parts have inherent anti-corrosion properties that make them less dependent on rust inhibitors. However, all metals still require regular cleaning cycles to prolong their operational lifespan. Our system customizations aim to determine the optimal wash formulas and processes for maintaining quality standards specific to the materials you utilize.

Evaluating your part types allows us to tailor the necessary degrees of corrosion prevention, specialized detergents, and cleaning intensities. We focus on designing a solution centered around your facility’s needs.

INDUSTRIES WHERE RUST AND CORROSION ARE A SIGNIFICANT CONCERN

Our rotary basket parts washers are especially critical for corrosion protection in steel part manufacturing. Aluminum and brass parts are less prone to corrosion due to their inherent properties, so they do not need specialized corrosion-prevention measures compared to steel.

Solving corrosion issues with parts washers in these industries requires a custom solution. All equipment containing metal parts will benefit from regular cleaning cycles. Proper washing maintenance removes built-up contaminants, extending operational lifespan. It also mitigates degradation from oxidation and part failure risk.

SOLVE YOUR RUST AND CORROSION PROBLEMS FOR GOOD

Arnold Machine leads the industry in rotary basket parts washer technology. Our rotary basket parts washers deliver reliable, permanent protection against any facility’s nagging rust and corrosion problems. Click below to explore our innovative parts-washing solutions.